Spiraltherm Graphite 9594

Spiraltherm Graphite 9594

Spiraltherm Graphite 9594

Features

Spiraltherm Graphite H 9594 is a flange seal made from a V-shaped profiled stainless steel tape with spiral-wound graphite middle layer (purity >99.85 %). The ends of the stainless steel tape are spot-welded.

Advantages

- Suitable for nuclear applications

- High purity graphite

Materials

- Filler material:

99.85 % pure graphite - Metal spiral:

1.4541 (321) or 1.4571 (316 Ti) - 9594/...R variants:

Sulfur content <100 ppm, soluble sulfates <100 ppm

Standards and approvals

- BAM (on request)

Recommended applications

Industries

- Chemical industry

- Petrochemical industry

- Power stations

- Compressors

- Valves

- Heat exchangers

- Covers and hatches

- Reactor vessels

- Process vessels

- Flange connections

- Pipe connections

- Maintenance seals

Variants

9584/... (98 % pure graphite filler)

9594/... (99,85 % pure graphite filler)

9594/...R (graphite filler with low sulfur < 200 ppm and water soluble sulfate < 100 ppm cont)

9584/...TZ (with additional PTFE-sealing zone, T < 280 °C)

9594/...TZ (with additional PTFE-sealing zone, T < 280 °C)

9595/... (pure PTFE filler, T < 280 °C)

9596/... (mica filler, T < 900 °C)

9594/... (99,85 % pure graphite filler)

9594/...R (graphite filler with low sulfur < 200 ppm and water soluble sulfate < 100 ppm cont)

9584/...TZ (with additional PTFE-sealing zone, T < 280 °C)

9594/...TZ (with additional PTFE-sealing zone, T < 280 °C)

9595/... (pure PTFE filler, T < 280 °C)

9596/... (mica filler, T < 900 °C)

Forms of supply

Rings:

for tongue-and-groove flanges - 9594/NF (standard), 9594/NFR (sulfur content <100 ppm)

for tongue-and-groove flanges, with compression curve - 9594/NFS (standard), 9594/NFSR (sulfur content <100 ppm)

for projection and recess flanges - 9594/VR (standard), 9594/VRR (sulfur content <100 ppm)

for projection and recess flanges, with inner ring - 9594/VRI (standard), 9594/VRIR (sulfur content <100 ppm)

for raised-face flanges, with outer ring - 9594/GA (standard), 9594/GAR (sulfur content <100 ppm)

for raised-face flanges, with inner and outer ring - 9594/GIA (standard), 9594/GIAR (sulfur content <100 ppm)

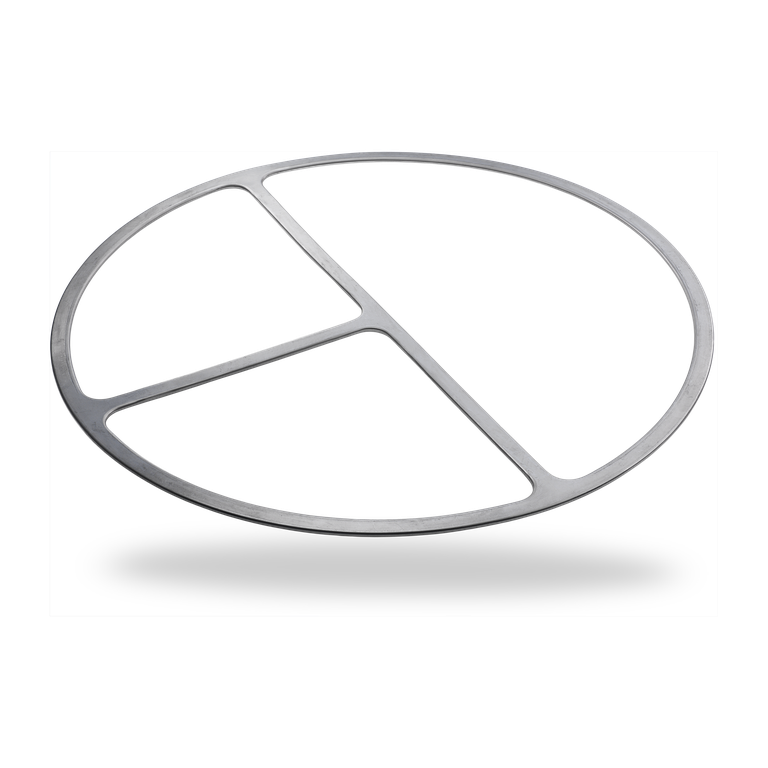

Manhole Gasket:

9594/MH (standard), 9594/MHR (sulfur content <100 ppm)

for tongue-and-groove flanges - 9594/NF (standard), 9594/NFR (sulfur content <100 ppm)

for tongue-and-groove flanges, with compression curve - 9594/NFS (standard), 9594/NFSR (sulfur content <100 ppm)

for projection and recess flanges - 9594/VR (standard), 9594/VRR (sulfur content <100 ppm)

for projection and recess flanges, with inner ring - 9594/VRI (standard), 9594/VRIR (sulfur content <100 ppm)

for raised-face flanges, with outer ring - 9594/GA (standard), 9594/GAR (sulfur content <100 ppm)

for raised-face flanges, with inner and outer ring - 9594/GIA (standard), 9594/GIAR (sulfur content <100 ppm)

Manhole Gasket:

9594/MH (standard), 9594/MHR (sulfur content <100 ppm)

Similar products

Buralloy Heat exchanger seal 2500

The Buralloy heat exchanger seal 2500 is a semi-metal gasket with a soft core and metal jacketing. The Buralloy 2500 thus combines the benefits of a compressible soft seal with the mechanical strength of a metal seal. As a result, it can be produced in many different material combinations and in different styles to suit the application.

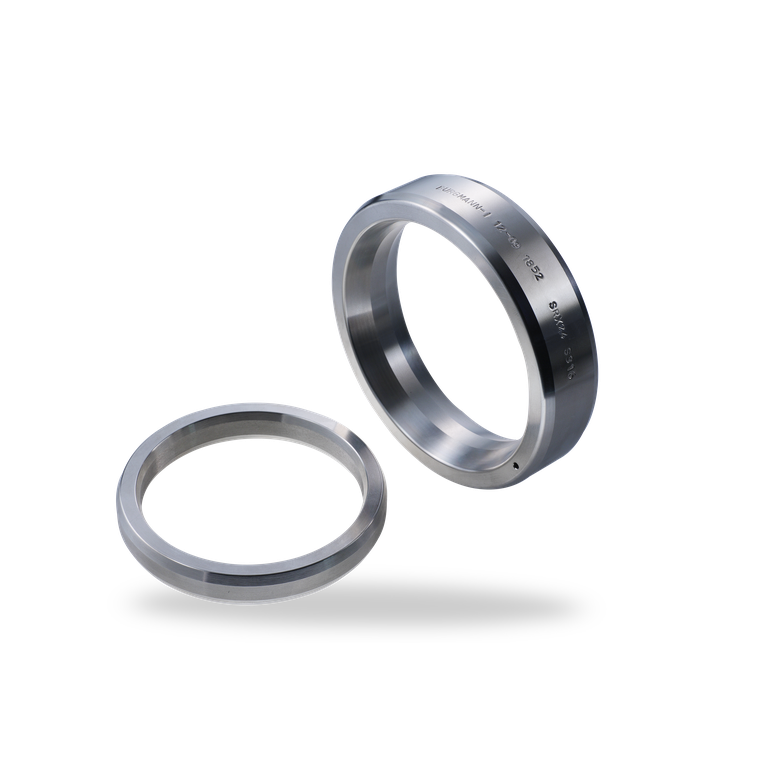

Buralloy Ring Type Joint 2961

Buralloy ring-type joint 2961 (RTJ) gaskets are manufactured from metallic materials in compliance with American standard ASME B 16.20 and the API specification. Detailed monitoring of every manufacturing step guarantees that the sealing rings offer the necessary surface hardness. This creates a functional seal without damage to the flanges. This gasket type is used successfully in downstream refinery applications, for example. RTJ gaskets are also commonly used in high-pressure valves and the associated pipe connections and in pressure vessel joints.

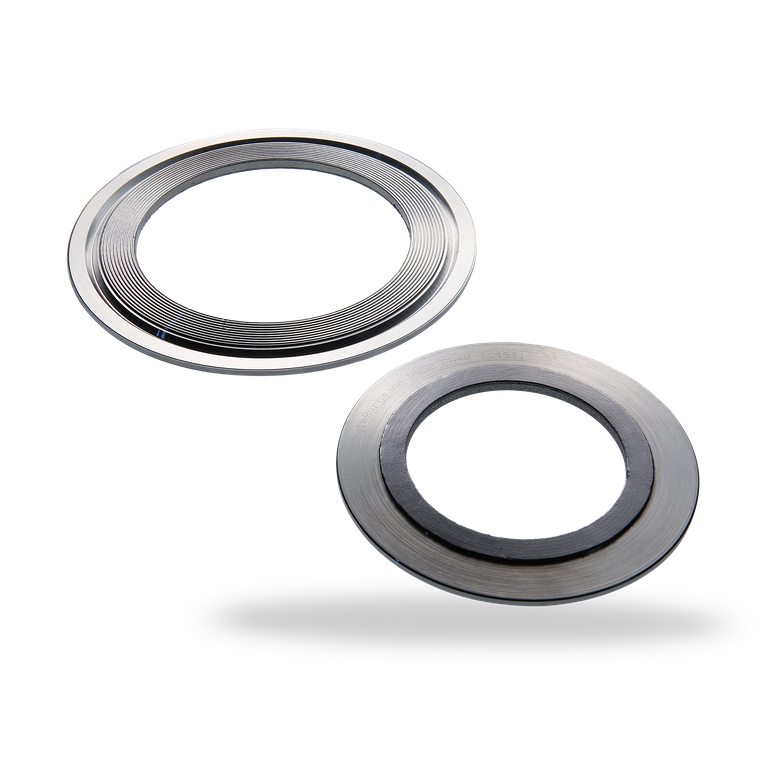

Camprofile serrated gasket 9588

The serrated gasket 9588 has a concentrically-machined profile based on a 4 mm thick stainless steel base plate. This is coated on both sides with a 0.5 mm thick layer of pure graphite (purity > 98%). Thicker layers are available on request. The serrated gasket 9588 is easy to handle and is particularly suitable for applications in the chemical and petrochemical industries and in power station technology.