MR-D

MR-D

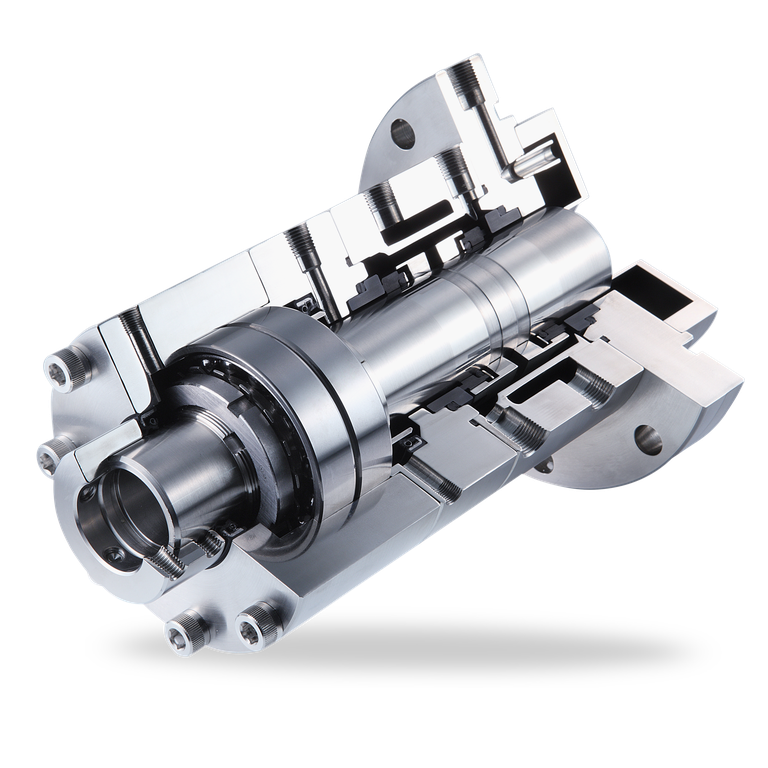

| Item | Description |

| 1 | Seal face, product side |

| 2 | Seat, product side |

| 3, 6 | O-Ring, dynamic |

| 4 | Seal face, atmosphere side |

| 5 | Seat, atmosphere side |

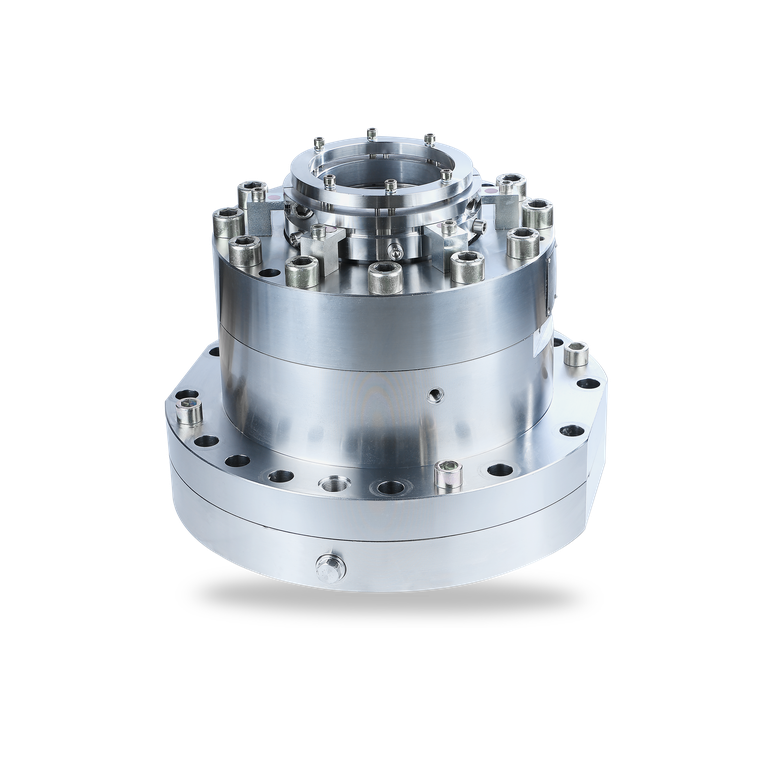

MR-D

Features

- For top, side and bottom entry drives

- Seat at product side rotating

- Unbalanced

- Liquid-lubricated

- Double seal

- Independent of direction of rotation

- Cartridge unit

- With or without bearing available

Advantages

- Smooth surface, free of dead spaces

- CIP-/SIP (Cleaning in Place, Sterilization in Place) capable

- Sliding materials FDA conform

- Variant for sterile applications available

- ATEX certification on request

Materials

Seal faces: Silicon carbide, FDA conform

Seat: Carbon graphite (atmosphere side) resp. Silicon carbide (product side), FDA conform

Secondary seals and metallic parts acc. to application and customers' requirement.

Seat: Carbon graphite (atmosphere side) resp. Silicon carbide (product side), FDA conform

Secondary seals and metallic parts acc. to application and customers' requirement.

Standards and approvals

- FDA

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Food and beverage industry

- Mixers

- Dryers

- Mills

- Kneaders

- Reactors

- Pressure filters

Notes

Options:

- Cooling resp. heating flange

- Temperature sensor

- Axial expansion joint (shaft movement)

- Wiper ring (shaft movement)

- Shaft sleeve not in contact with product (with standard diameters)

- Metal-free on product side

Recommended piping plans

Closed circuit: EagleBurgmann TS system, EagleBurgmann DRU pressure booster,

Open circuit: EagleBurgmann SPA / SPN

Product links:

EagleBurgmann TS1000

EagleBurgmann TS2000

EagleBurgmann TS3016 (sterile version)

EagleBurgmann DRU

EagleBurgmann SPA

EagleBurgmann SPN manual

EagleBurgmann SPN automatic

Open circuit: EagleBurgmann SPA / SPN

Product links:

EagleBurgmann TS1000

EagleBurgmann TS2000

EagleBurgmann TS3016 (sterile version)

EagleBurgmann DRU

EagleBurgmann SPA

EagleBurgmann SPN manual

EagleBurgmann SPN automatic

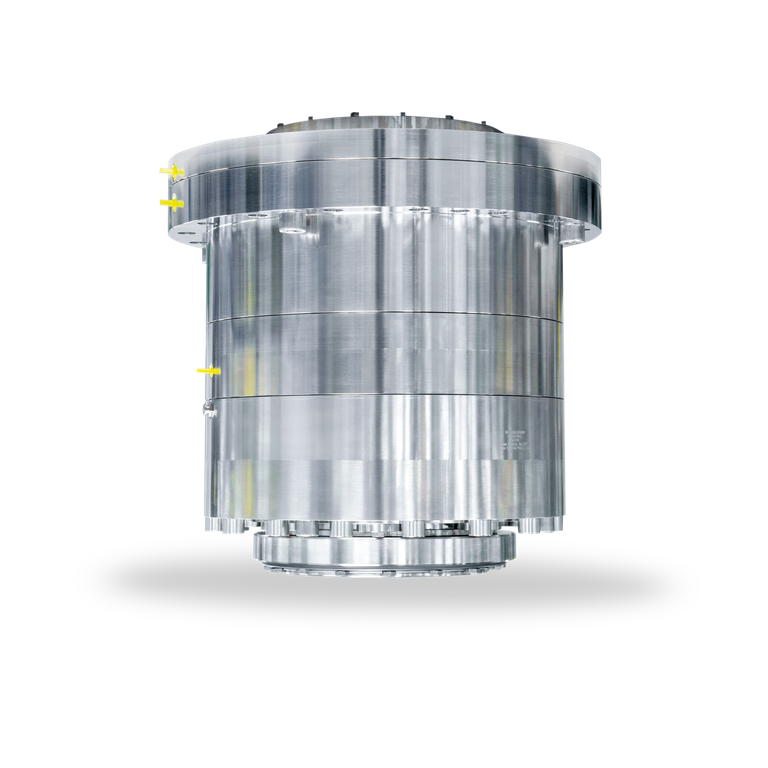

Similar products

ERB

- Cartridge unit

- Double seal with integrated bearing

- Unbalanced

- Independent of direction of rotation

HS-D

- For top entry drives

- Double seal

- Unbalanced

- Independent of direction of rotation

- Multiple springs rotating

- Liquid-lubricated

- Cartridge unit

HSH(L)U-D

- For bottom entry drives

- Double seal

- Balanced

- Independent of direction of rotation

- Multiple springs rotating

- Liquid-lubricated

- Cartridge unit