Penetration seal

metal expansion joints

Penetration seal

metal expansion joints

Penetration seal (with telescopic covers option)

area cross section.

* Shown for illustration only.

area cross section.

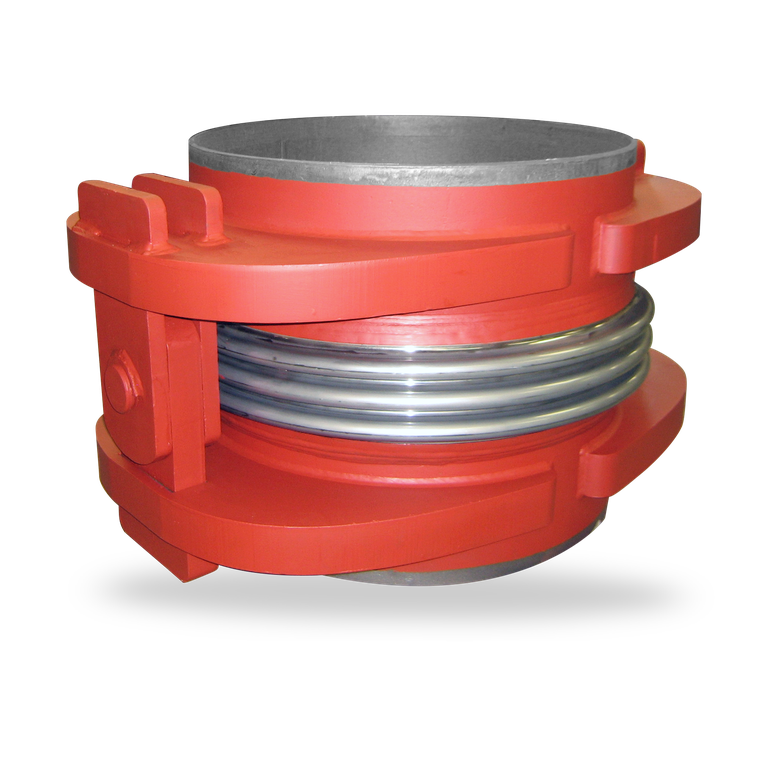

| Item | Description |

| 1 | Bellows |

| 2 | Outside ring |

| 3 | Inside ring |

| 4 | Drain plug (optional) |

| 5 | Cover ring (optional) |

| 6 | Inside cover (optional) |

| 7 | Outside cover (optional) |

| 8 | Boiler wall* |

| 9 | Penetration pipe* |

* Shown for illustration only.

Penetration seal

metal expansion joints

Features

- 100 % airtight solution to boiler penetration.

- Permits axial and lateral movement without causing high stresses in penetration pipe and boiler wall.

- Maintenance-free

- Used in heat recovery steam generators (HRSGs).

Advantages

- Improved boiler efficiency through zero gas seepage.

- Improved boiler efficiency through reduced heat loss.

- No emissions

- Noise reduction

Materials

- Bellows material options: 1.4301(ANSI 304), 1.4404 (ANSI 316/L dual-certified), 1.4541 (ANSI 321), Inconel® 600, Inconel® 625, 254 SMO®, Incoloy® 25-6HN.

- Bellows basics: formed by punch mandrel, thin-wall ply thickness ≤1.5 mm (0.060”).

- Rings, bands: carbon steel, chrome-moly.

- Metal covers: carbon steel, stainless steel.

Standards and approvals

- GE Specification

- Expansion Joint Manufacturers Association (EJMA)

- ISO 9001:2008

Recommended applications

- Power plant technology

- Refining technology

- HRSGs (heat recovery steam generators)

Functional description

Metal expansion joints are used in pipelines to compensate for thermal growth, typically in applications with high internal temperatures; or to prevent vibrations from being transmitted beyond the expansion joint.

Notes

Standard quality control and testing:

Service:

- Air and soap bubble leak check.

Service:

- Skilled field service teams can provide site support.

- Expert clamshell (split bellows, for in situ repair) bellows welders.

- Experienced supervision by our field service personnel available.

Similar products

AN Type expansion joints

- Tied custom metal expansion joints for general pressure applications.

- Designed for, and cover the mid temperature and pressure range for general process equipment.

- Mainly for angular movements.

- Tied metal expansion joints retain pressure thrust developed by internal pressure, through the use of hardware.

AX Type expansion joints

- Untied custom metal expansion joints for general pressure applications.

- Designed to cover the mid temperature and pressure range for general process equipment.

- Mainly intended for axial movements.

- Multiply bellows with low spring rate and high cycle life.

CB Clamshell metal expansion joints

- Bellows or expansion joints split into longitudinal segments for installation without opening pipework.

- Temporary repair solution for damaged expansion joints.

- Can handle axial, lateral and angular movements.

- The permissible combination and magnitude of movements depends on the application and the existing expansion joint that is to be repaired.