Fluastal

expansion joints

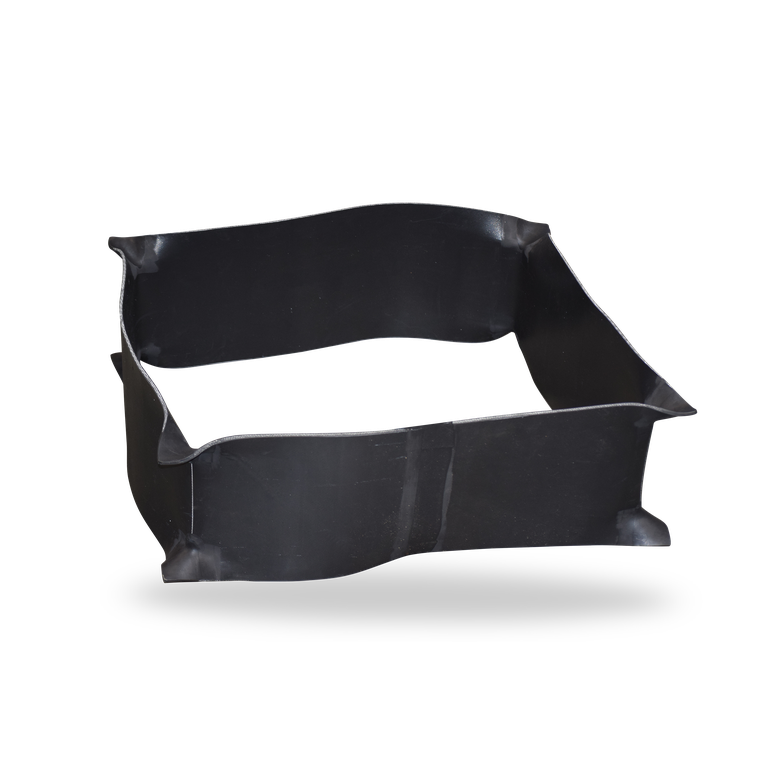

Fluastal

expansion joints

| Item | Description |

| 1 | Flange reinforcement |

| 2 | Pressure carrying layer / gas seal layer |

| 3, 4 | Insulation layer |

| 5 | Support layer |

| 6 | Mechanical reinforcement |

Fluastal

expansion joints

Features

- Multi layer design

- Compensates for movements in several directions simultaneously

- Excellent form stability

- Can be delivered as fabric only or as preassembled unit

- Custom made to fit actual working conditions

Advantages

- Highly flexible

- High chemical resistance

- High flutter resistance

- Reduced heat loss

- Low reaction forces

- Good resistance against abrasion

- Suitable for high temperature applications

Standards and approvals

Documentation:

- EN 10204-2.2 certificate

- Safety Data Sheets (SDS) for individual materials

- EN 10204-2.2 certificate

- Safety Data Sheets (SDS) for individual materials

Recommended applications

- Process industry

- Oil and gas industry

- Pharmaceutical industry

- Power plant technology

- Metal production and processing

- Cement industry

- Flue gas duct systems

- Boiler inlets and boiler outlets

- Penetration seals

- Process lines

- Stack connections

Functional description

Fluastal expansion joints safely absorb thermal expansion and misalignments in pipe and duct systems in dry and high temperature area. Flexgen products compensate for movements in multiple directions simultaneously.

Product variants

Pre-assembled units

Pre-assembled expansion joint units consist of:

- Fabric expansion joint

- Metal frames/inner sleeves

- Gasket (optional)

- Fasteners

Frame material:

- Carbon steel

- Stainless steel

- Heat resistant steel

Pre-assembled expansion joint units can be supplied with surface treatment that is corrosion resistant (standard) and resistant to high temperatures. EagleBurgmann KE offers any RAL color code for the units. Units can be delivered with seaworthy packing or standard packing for road transportation.

- Fabric expansion joint

- Metal frames/inner sleeves

- Gasket (optional)

- Fasteners

Frame material:

- Carbon steel

- Stainless steel

- Heat resistant steel

Pre-assembled expansion joint units can be supplied with surface treatment that is corrosion resistant (standard) and resistant to high temperatures. EagleBurgmann KE offers any RAL color code for the units. Units can be delivered with seaworthy packing or standard packing for road transportation.

Similar products

Acouseal expansion joint

- Single layer design

- Designed for acoustic demanding environment in GT inlets

- Absorbs movements and vibrations in multiple directions

- 100 % gas tight connection

- Excellent and proven sound reducing properties

Combine-X expansion joints

- Multi layer design

- Compensates for movements in several directions simultaneously

- Excellent form stability

- Can be delivered as fabric only or as preassembled unit

- Custom made to fit actual working conditions

- Specifically designed for gas turbine systems

Flexgen expansion joints

- Multi layer design (Flexgen 2002: single layer construction)

- Compensates for movements in several directions simultaneously

- Can be delivered as fabric only or as preassembled unit

- For dry condition

- Custom made to fit actual working conditions