Situation

Darlington Nuclear Generating Station with 16 Sulzer single-stage vertical reheater drain pumps

Darlington Nuclear Generating Station with 16 Sulzer single-stage vertical reheater drain pumps

Large temperature differences and high pressure led to inadequate cooling

SHFV1/42-E1, a new sealing system with API plan 23

Darlington Nuclear Generating Station is located 70 km east of Toronto (Canada). The four unit station is the newest generating station of Ontario Power, performs a total output of 3,512 MW and provides about 20 % of Ontario‘s electricity needs - enough to serve a city of two million people.

16 Sulzer single-stage vertical reheater drain pumps type BJ3X4X11 model TXR are installed. The second stage reheater drains system drains the condensate, and vents any uncondensed steam from the second stage reheater tube bundles and directs these to the steam generator and the HP heater.

The pumps in question were originally equipped with a competitor‘s seal system, operated acc. to API plan 41. High temperature and high pressure caused problems for the seal and its supply system. Because of large temperature differences between the cold cooling medium (lake water) and the hot process medium (demineralized water) an excessive deposit of cooling water sediment occured and the coil of the heat exchanger regularly plugged. Therefore, inadequate cooling was provided which resulted in dry running of the seal faces and ended in seal failure.

These failures occurred up to 10 times a year and caused a loss of efficiency of 4 MW, costing 5,000 CAD per day.

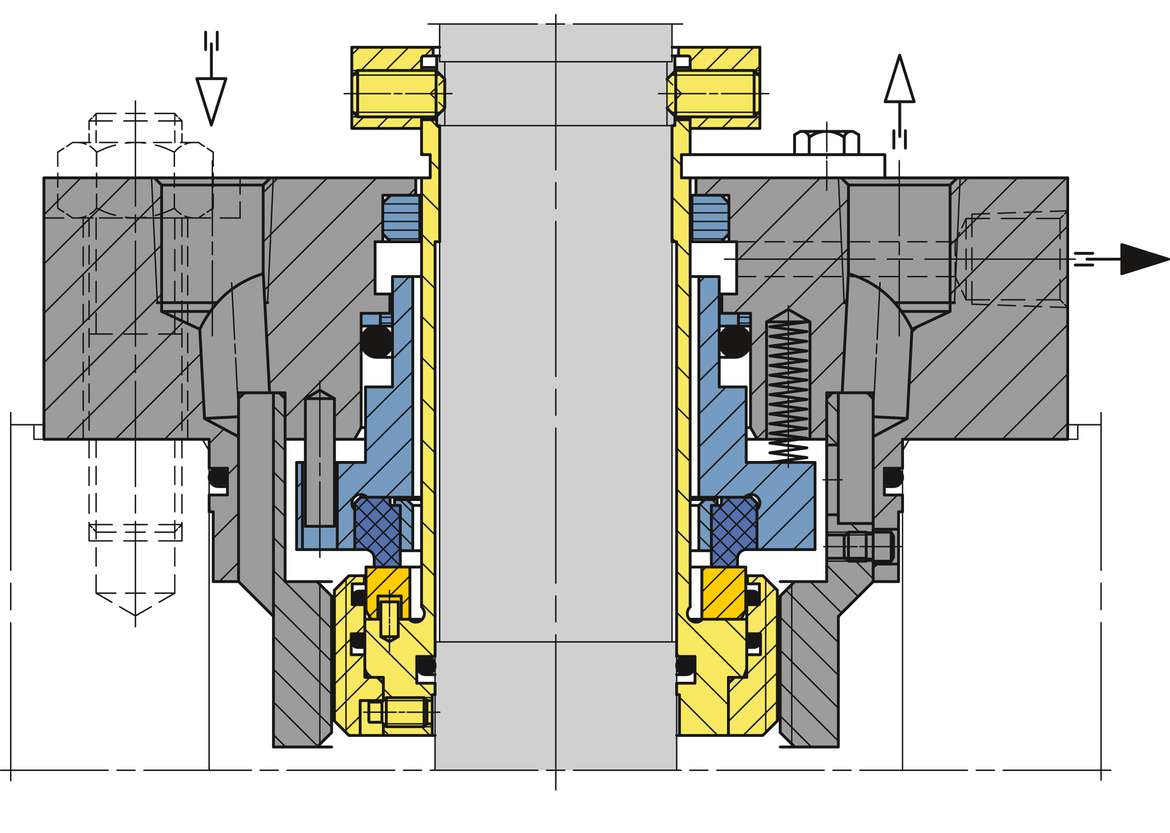

Illustr. 1: SHFV High pressure mechanical seal for boiler circulation pumps. Dual seal in tandem arrangement, with pumping screw

Illustr. 2: Yellow parts = rotating, blue = stationary, gray = housing

EagleBurgmann designed a new sealing system, the SHFV1/42-E1 with API plan 23. This system had to pass through a performance test at the EagleBurgmann facilities in Wolfratshausen, Germany. The test was arranged with the original equipment and under operation conditions of Darlington Nuclear. All tests have been performed successfully without any problems.

The first SHFV1/42-E1 with API plan 23 was installed in 2007. Another 15 sealing systems follwed in 2008. Since start-up the seals show excellent performance and run without any problems.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.

The new zero-emission mechanical seal from EagleBurgmann prevents the emission of the greenhouse gas methane during natural gas extraction, transport and processing.

The reliability of centrifugal compressors in gas grids are of the highest social and economic importance for network operators. Compressor performance and availability are closely related to the effectiveness of sophisticated compressor shaft sealing technology. Here, EagleBurgmann developed a new sealing concept which ensures better compressor availability: the coaxial separation seal CobaSeal.

They are often overlooked but play a crucial role when it comes to sustainability: modern and complex sealing solutions. Digital technologies now enable remote monitoring, helping to increase their service life and therefore reduce their ecological footprint.