Situation

High-boiling toxic product is separated from the residue by evaporation in a steel distillation vessel

M481KL shaft seal for distillation units

High-boiling toxic product is separated from the residue by evaporation in a steel distillation vessel

Problematic media, and original sealing solution was not conform to current industrial standards

TA-Luft- and ATEX-compliant mechanical seal, type M481KL-D24

In the process stage presented here, a high-boiling toxic product is separated in a steel distillation vessel at Chema Prozess- und Systemtechnik (Germany) from the residue by evaporation. The distillation vessel is run discontinuously in batch operation. This means that the vessel is filled at the beginning of the process and then heated up to the operating temperature. Due to different boiling points the product is separated by distillation. When the vessel has cooled down, the residue is removed and the vessel is refilled.

The medium to be separated has a melting point of 155 °C and a tendency to resublimate, i.e. it changes its state of aggregation directly from gaseous into solid. This tendency to resublimate is problematic because product deposits can build up on the seal and can lead to the seal hanging up.

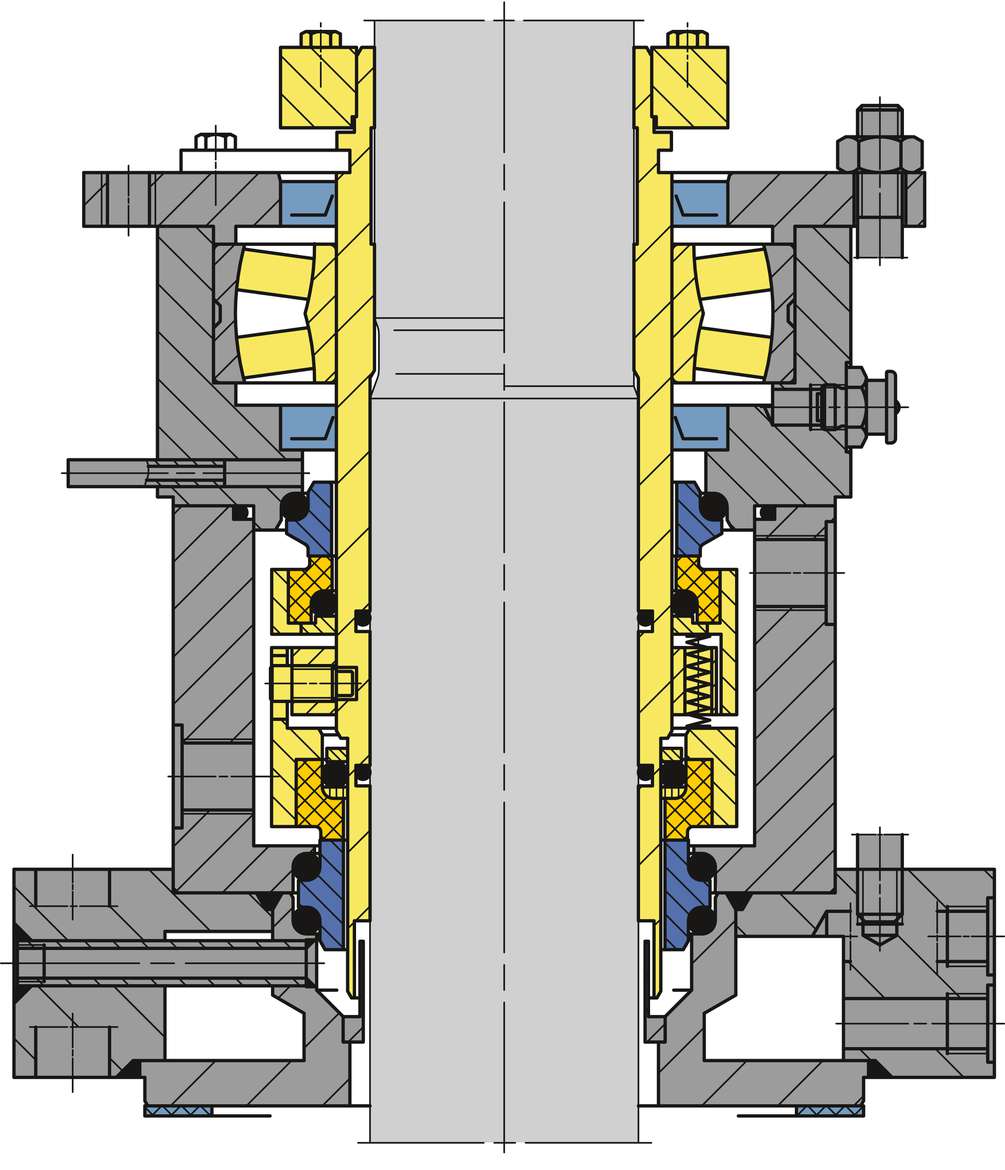

Illustr. 1: M481KL agitator seal

Illustr. 2: Yellow parts = rotating, blue = stationary, gray = housing.

Until now, the sealing was performed using a double packing with a flush. The problem with this sealing solution was that it was not conform to current industrial standards based on the today’s legislation such as TA-Luft and ATEX. In order to fulfill these requirements, the stuffing box packing was replaced by TA-Luft-compliant mechanical seal, type M481KL-D24, which is conform to ATEX Zone 1 II GD cb T3. The seal is a double mechanical seal with integrated bearing in cartridge design. The seal is self-closing.

Special features include an integrated “cooling flange” and the use of a polymerization barrier. However, in this application the “cooling”-flange is not utilized for cooling but for heating, in order to prevent product resublimation. Temperatures produced here range between 155 °C and 200 °C.

The polymerization barrier, which is a sort of labyrinth, is arranged below the seal on the product side and is continually flushed with nitrogen. This prevents the medium from reaching the seal and forming a deposit, resulting in the seal hanging up. Normally, polymerization barriers utilize liquid quench media.

Originally, it was proposed to use a medicinal grade white oil. However, the fact that this produced minor leakage into the product was unacceptable to the customer. It was therefore decided to go with nitrogen as the flush medium without retro-fitting of the seal. It is recommended to use a throttle for gaseous media in order to achieve higher flow rates. It is also possible to achieve precise drain-off of any leakage in order to fulfi ll TA-Luft air quality control requirements.

Specifically because of the high temperatures involved, a special perfluoro rubber (KH) that is resistant up to 315 °C is used for the elastomers on the product side and to some extent on the atmosphere side as well.

With this contemporary seal solution the plant operator rebuilt its equipment right up to current industrial standards and to fulfill the demands of legislation in every respect as set out by TA-Luft and ATEX. Emissions are reduced to a minimum and security of employment also achieves significant improvement. In addition, the seal’s lifetime is also noticeably prolonged.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.

The new zero-emission mechanical seal from EagleBurgmann prevents the emission of the greenhouse gas methane during natural gas extraction, transport and processing.

The reliability of centrifugal compressors in gas grids are of the highest social and economic importance for network operators. Compressor performance and availability are closely related to the effectiveness of sophisticated compressor shaft sealing technology. Here, EagleBurgmann developed a new sealing concept which ensures better compressor availability: the coaxial separation seal CobaSeal.

They are often overlooked but play a crucial role when it comes to sustainability: modern and complex sealing solutions. Digital technologies now enable remote monitoring, helping to increase their service life and therefore reduce their ecological footprint.