Situation

The seal must protect employees, machinery and buildings from chemicals

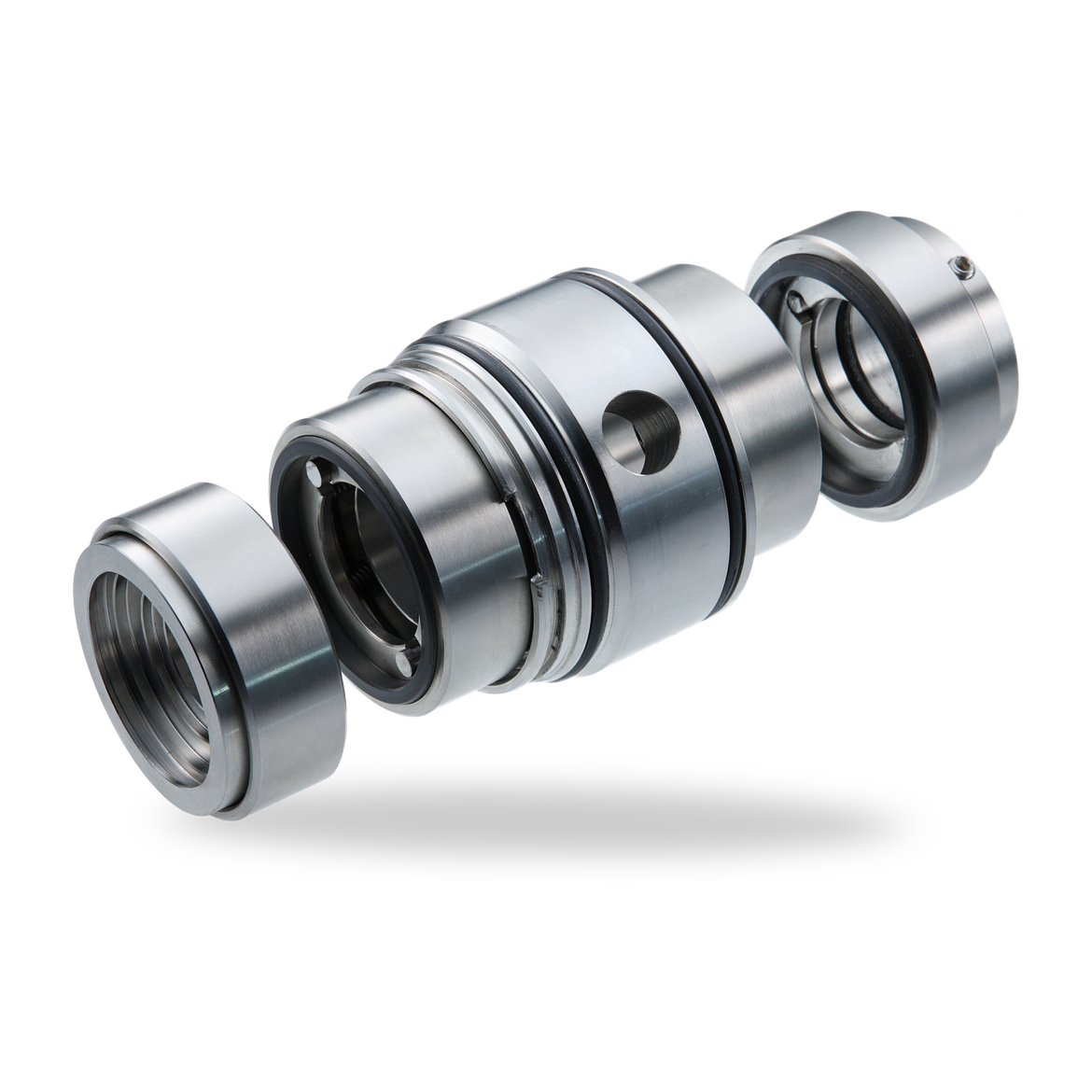

Mechanical seal LP-D for a pressure disk filter

The seal must protect employees, machinery and buildings from chemicals

Enable simple assembly and disassembly, reduce maintenance requirements

Cartridge seal LP-D from EagleBurgmann

A typical pulp mill in Europe produces over 400,000 tons of pulp and 80,000 tons of paper per year. Smooth production of elemental chlorine-free bleached (ECF) long fiber sulfate pulp also relies to a great extent on the sealing technology used in the individual processes.

Seals in the liquor line perform the important task of protecting employees, machinery and the building from the chemicals that are recovered there for pulp production. EagleBurgmann convinced the persons responsible for the liquor line of a customer to equip the shaft of the pressure disk filter with the practical and reliable cartridge seal LP-D, thus reducing maintenance costs in the long term.

The pressure disk filter separates white liquor from lime slurry. The mechanical seal from EagleBurgmann is mounted on both the drive and non-drive sides of the shaft. It is double-acting, i.e. it reliably prevents the caustic and hot white liquor from reaching the atmosphere. Since the medium is injected on the drive side of the shaft, the seal on that side has more contact with the caustic white liquor. As there always is only one filter in the recovery island, a seal failure would always cause an unplanned shutdown of the complete pulp mill. Therefore reliability is the key criteria for the seal design.

The seal is specially adapted for use in filter machines of well-known manufacturers for the paper and pulp industry. The robust LP-D has various distinctive design features. For example, the dynamic O-ring is not located directly on the shaft, but within the seal. The design of the stationary seal face on the product side prevents deposits of white liquor in the groove of the O-ring which would block the compensating movements of the seal. Stationary springs on the product and atmosphere side counteract leakage by compensating shaft movements to keep the sealing gap consistently closed.

The wall thickness of the shrink fits is generously dimensioned to dissipate heat from the seal and prevent deformation of the sliding faces. Also, the seal faces are made of robust materials to prevent wear caused by the abrasive, hard particles of the lime slurry. The seal is supplied with pressurized buffer water for optimum supply and to prevent the medium from penetrating the seal.

The failure of one seal would inevitably lead to a standstill of the entire recovery unit. Understandably, the customer placed great value on a reliable seal and a simple assembly and disassembly process. Since the seal from EagleBurgmann is a cartridge design, work on the five-ton shaft can be completed relatively quickly.

To ensure convenient and reliable fixing of the seal during transport, assembly and disassembly, the assembly fixtures are made of robust material and are dimensioned accordingly. The shaft sleeve is so stable that it can withstand many assembly and disassembly processes.

The LP-D mechanical seal from EagleBurgmann has been used satisfactorily in the pulp mill on the drive and non-drive side of the shaft since 2010. The MTBR of three years exceeded the expectations of the operators and reduced the costs for the seal service to a minimum.

Operating conditions

From mechanical seals for economical and reliable non-flow operation to the use of new instruments for seal supply with simultaneous monitoring of the mechanical seals - EagleBurgmann has practical solutions: Depending on the application, various control units are used to regulate and optimize the water supply.

Pumps, agitators, chest agitators, pulp digesters, washers and sorters are sealed with mechanical seals of the LP, M7, Cartex, MG and HJ series. In addition, Buraflon-type stuffing box packings seal numerous machine shafts in the process.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.

The new zero-emission mechanical seal from EagleBurgmann prevents the emission of the greenhouse gas methane during natural gas extraction, transport and processing.

The reliability of centrifugal compressors in gas grids are of the highest social and economic importance for network operators. Compressor performance and availability are closely related to the effectiveness of sophisticated compressor shaft sealing technology. Here, EagleBurgmann developed a new sealing concept which ensures better compressor availability: the coaxial separation seal CobaSeal.

They are often overlooked but play a crucial role when it comes to sustainability: modern and complex sealing solutions. Digital technologies now enable remote monitoring, helping to increase their service life and therefore reduce their ecological footprint.