Situation

- Seal usually lies in the product, crystals agglomerate

Double seal AGSR for a vacuum paddle dryer

Situation

Challenge

Solution

Liquid crystals are complex organic compounds that are used, for example, in LCD flat screens (LCD = liquid crystal display). Electric voltage influences the orientation of the liquid crystals and the resulting light transmittance makes it possible to display the image. Even the smallest impurities in the production of liquid crystals affect their conductivity.

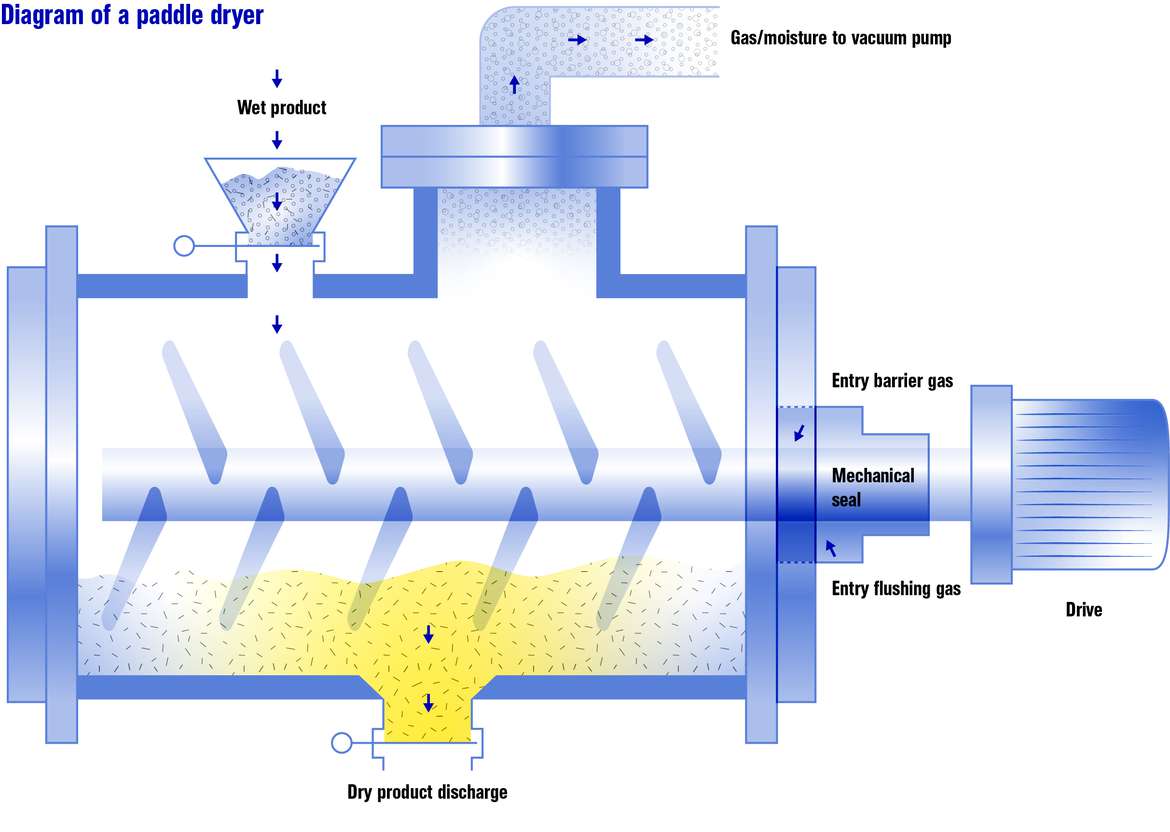

For many years, the Performance Materials business unit of Merck KGaA in Darmstadt/Germany has been using gas-lubricated mechanical seals of the AGSR series from EagleBurgmann that meet the demanding requirements for purity and cleanability in the production of liquid crystals. The seals are installed on the shafts of the side drives of several horizontal paddle dryers in which the crystals are dried.

The crystals are usually produced in a batch process and are present in various solvents such as toluene or methanol. Because of their physical properties, the crystals can easily accumulate on the seal. It is therefore essential to continuously flush the seals during operation. They must also be suitable for CIP processes (CIP = Cleaning In Place) in order to prevent subsequent batches from being contaminated by previous production and to ensure the function of the seal.

In horizontal paddle dryers such as those used at Merck, the seals are also usually to be found in the product. It is therefore necessary to reliably prevent contamination from the barrier medium used as well as abrasion from the sliding faces. A further requirement for the sealing system was compliance with Directive 94/9/EC (ATEX 95) or 2014/34/EU, which regulates the commissioning of machines in potentially explosive atmospheres.

The AGSR mechanical seal from EagleBurgmann is a gas-lubricated double seal. Since the seal faces run without contact, contamination through abrasion from the sliding faces is avoided from the outset. Specific design features of the seal, such as smooth surfaces in contact with the product and an open O-ring groove design, contribute to optimized cleanability. As a result, the seal is also suitable for sterile applications. A flushing system integrated in front of the dynamic sealing element on the product side is permanently supplied with nitrogen during operation. It also simplifies cleaning using the CIP process. This increases the operational reliability of the seal because it reliably removes product residues.

Dry nitrogen is used as barrier and flushing medium. As an inert gas, it is slow-reacting and therefore suitable for use in potentially explosive atmospheres. Large sealing surfaces in conjunction with an appropriate groove design ensure a high rigidity of the gas film and thus a reliable sealing function and low nitrogen consumption.

In addition to regular CIP cleaning via the flushing gas connection, the continuous application of buffer and flushing gas contributes to the extension of service life. This protects the seals even during standstill. As a further measure to increase the service life, regular buffer gas pressure surges were established during drying. Despite the demanding operating conditions, the gas-lubricated mechanical seals AGSR at Merck achieve a long service life of several years in practice.

AGS agitator seals – For maximum product purity. Designed for reactors, mixers, dryers and special machine.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.

The new zero-emission mechanical seal from EagleBurgmann prevents the emission of the greenhouse gas methane during natural gas extraction, transport and processing.